Vertical Lift Module (VLM) Sistema de almacenamiento en estanterías cerradas diseñado para aumentar la capacidad en un espacio más compacto.

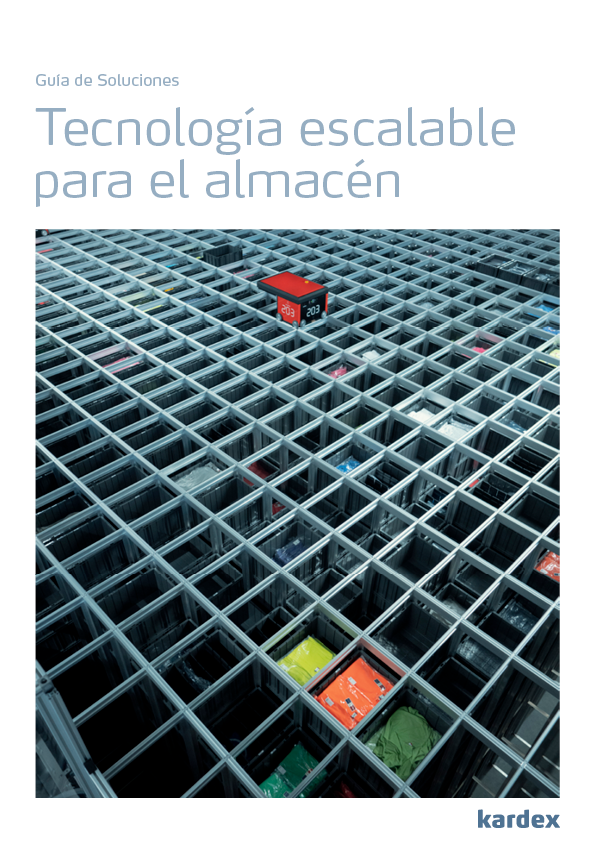

Saber máSoluciones AutoStore™ totalmente integradas Lleve el picking al siguiente nivel.

Descubra ahoraOptimice el espacio del almacén Implemente la automatización para aumentar la capacidad de almacenamiento y minimizar la huella

Saber más¿Enfrentando desafíos con espacio limitado? Explora los principales métodos de optimización del espacio y tecnologías avanzadas.

Saber másRevolucione su proceso de picking Mejore la velocidad y la precisión de picking.

Lea ahoraSoluciones por sector industrial

¿Cómo almacena los productos?

Un almacenamiento automatizado de cajas evolucionado

Optimice los procesos intralogísticos con la nueva solución de almacenamiento automatizado de cajas. Gracias a su precisión, este sistema de picking y almacenamiento intermedio de cajas mejorará considerablemente sus procesos de gestión de pedidos y le permitirá ahorrar espacio.

.jpeg)